Ligne De Production De Big Bag GTIP-11062

Extruder

| No. | Item | Description and Quantity | Remarks |

| 1 | Screw diameter | 90 mm | |

| 2 | Screw L/D | 30 : 1 | |

| 3 | Screw material | SCM-1 | |

| 4 | Cylinder material | SCM-1 | |

| 5 | Transmission power | 75 hp with inverter | |

| 6 | Heater capacity | 28 kw | |

| 7 | Auto hopper loader capacity | 150 kgs (included force material feeding unit) | |

| 8 | Auto hopper loader power | 2 HP | |

| 9 | Maximum PP melting output | 240 kg/hour | |

| 10 | Maximum HDPE melting output | 170 kg/hour | |

| 11 | Type of filter | Belt type screen filter changer | |

| 12 | Extruding pressure meter | Equipped | |

| 13 | Gear box | ||

| 14 | Gear box cooling system | Equipped |

T-Die

| No. | Item | Description and Quantity | Remarks |

| 1 | T-die width | 900 mm | |

| 2 | Number of flat yarn | 154 pieces | |

| 3 | Film width | 800 mm | |

| 4 | Heating capacity | 12 kw | |

| 5 | Heating method | Heating pipe | |

| 6 | Die gap application | 0.3 mm to 0.6 mm |

Control Panel

| No. | Item | Description and Quantity | Remarks |

| 1 | Type | Single type controller box | |

| 2 | 12 Points thermal controller | ||

| 3 | Emergency stop control | Equipped |

Cooling Device

| No. | Item | Description and Quantity | Remarks |

| 1 | Type | Water type | |

| 2 | Cooling method | Water circulation | |

| 3 | Quench system | Water bath system | |

| 4 | Cooling Tower | 1 set |

Take-off Unit A

| No. | Item | Description and Quantity | Remarks |

| 1 | Take-off roller | Æ190 mm x 950 mm x 2 pieces | |

| 2 | Press roller | Pneumatic system x 1 piece | |

| 3 | Powerful water suction unit | 3 hp | |

| 4 | Three wheel type stretching unit | Driving motor : 3 hp with inverter | |

| 5 | Edge trim auto recycle unit

Press roller Included 1 piece of rubber pressing roller |

1 set

Æ190 mm x 950 mm x 3 pieces |

|

| 6 | R.P.M. Display | 5~60 m/min | |

| 7 | Rotary slitting blade | 1 set | |

| 8 | Edge trim auto recycle unit | 1 set / 5 hp | |

| 9 | Electrical control panel | 1 set | |

| 10 | Emergency stop control | Equipped |

| No. | Item | Description and Quantity | Remarks |

| 1 | Type | Oven (Hot air circulation type) | |

| 2 | Oven size | 950 mm x 4000 mm x 1 set | |

| 3 | Blower motor | 2 hp x 2 pieces | |

| 4 | Stretching ratio | 4 to 8 times | |

| 5 | Heating capacity | 30 kw | |

| 6 | Air compressor | 1 set / 10 hp (Piston type) | |

| 7 | Air flow volume control | Equipped | |

| 8 | Air flow direction controller | Equipped | |

| 9 | Temperature zone | 1 set |

Take-off Unit B &Annealing (Relaxation) Unit

| No. | Item | Description and Quantity | Remarks |

| 1 | Take off roller | Æ318 mm x 900 mm x 7 pieces | |

| 2 | Pneumatic type press roller | 1 piece | |

| 3 | First four stretching rollers including | Drive motor : 15 hp inverter

Heating plate : 1 set Heating capacity : 7.5kw |

|

| 4 | Last three annealing roller including | Drive motor : 10 hp inverter

Chill roller : 2 pieces R.P.M. display : 0 ~ 320 m/min |

|

| 5 | Static electricity eliminator | 1 set | |

| 6 | Waste yarn collector | 1 set / 15 hp | |

| 7 | Emergency stop control | Equipped |

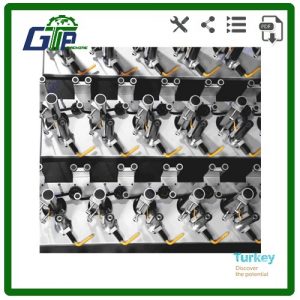

Winding Machine:

| No. | Item | Description and Quantity | Remarks |

| 1 | Number of winder | 154 pieces | |

| 2 | Model | Inverder 420 | |

| 3 | Speed control | Electronic Tension Control | |

| 4 | Winding tension adjustment | Spring loaded graduated collar | |

| 5 | Winding motor | 0.12kw x 154 pieces | |

| 6 | Flat yarn wind-up roll | Æ130 mm x 200 mm (1) | |

| 7 | Maximum mechanical winding speed | 400 M/min |

General

| No. | Item | Description and Quantity | Remarks |

| 1 | Tape line speed | 100~280 m/min. | |

| 2 | Flat yarn size application | 2.5mm ~ 4 mm | |

| 3 | Denier application | 750 ~ 1,200 | |

| 4 | Total power | 310 hp | |

| 5 | The winder speed varies according to the denier of the flat yarn that means different denier of flat yarn will have different speed. | ||

| 6 | The customer undertakes the electrical wires, air & water pipes from Factory entrance to the Control panel and seller undertakes everything from Control panel to machineries. | ||

| 7 | For producing more than 1,500 denier of flat yarn should be informed in the advance. | ||

| No. | Item | Description and Quantity | Remarks |

| 1 | Heating ring | HY7/SP-90HE-01 x 2 pc | |

| 2 | Heating plate for T-die | HY7/SP-90HE-02x 2 pc | |

| 3 | Heating pipe | HY7/SP-90HE-03 x 3 pc | |

| 4 | Thermo controller | HY7/SP-90HE-04 x 2 Sets | |

| 5 | Thermo couple | HY7/SP-90HE-05 x 2 pcs | |

| 6 | Ampere meter | HY7/SP-90HE-06 x 2 pcs | |

| 7 | Fuse | HY7/SP-90HE-10 x 6 sets | |

| 8 | Relay | HY7/SP-90HE-11 x 2 pcs | |

| 9 | Screen mesh 100 | HY7/SP-90HE-12x 1 roll | |

| 10 | Transmitting V-belt | HY7/SP-90HE-17 x 1 pc | |

| 11 | Yarn slitter | 15 pcs | |

| 12 | Speed regulator | 2 pcs | |

| 13 | Magnetic contactor | HY7/SP-90HE-07 x 2 pcs | |

| 14 | Selective switch | HY7/SP-90HE-08 x 5 sets | |

| 15 | Slitter blade | HY7/SP-90HE-09 x 600 pcs | |

| 16 | Handle of yarn slitter | 10 pcs | |

| 17 | Connector | 1 pc | |

| 18 | Coil of electromagnetic valve | 1 pc | |

| 19 | Electromagnetic valve | 1 set |

Specification:

| No. | Item | Description and Quantity | Remarks |

| 1 | Yarn to be used | PP or HDPE materials | |

| 2 | Quantity of shuttle | 8 pcs | |

| 3 | Total of warp picks | 2560 pcs | |

| 4 | Width of cloth | 1800 to 2200 mm | |

| 5 | Speed max | 70 RPM per shuttle | |

| 6 | Weft density | 3 – 6 picks/cm | |

| 7 | Main motor | 10 hp with inverter | Telemechanique |

| 8 | Winder | 2 hp | |

| 9 | Weft diameter | Max. Æ115 mm | |

| 10 | Winding method | Center shaft winding method | |

| 11 | Warp guiding roller | 4 sets equipped | |

| 12 | Weft auto-Stop | 2 pcs, weft break sensor & bobbin sensor | |

| 13 | Warp auto-stop | Touch system | |

| 14 | 1,280 spindle warp creel stand | 2 sets | |

| 15 | Winder | 1 set | |

| 16 | Pull cloth roller | 1 set | |

| 17 | Step plate | 1 set | |

| 18 | Separate yarn plate | 8 pcs (4 big + 4 small) | |

| 19 | Yarn hook | 2560 pcs | |

| 20 | Gear of weft density | 1 set | |

| 21 | Warp stop plate | 2560 pcs | |

| 22 | Warp stop spring | 2560 pcs | |

| 23 | Stretching tubular stand | 1 set | |

| 24 | Electronic control box | 1 set | |

| 25 | Loom controller | HMI/ PLC/ 5.7” touch screen monitor | |

| 26 | Dimension (L x W x H) | 16,000mm x 4,000mm x 4,500mm | |

| 27 | Weight | Approx. 7,500 kg |

| No. | Commodity description |

| 1. | Gearless weft density controller |

| 2. | Driving system for warp in-feed roller, include driving motor + electrical controller |

| 3. | In-line gusseting device |

| 4. | Center unfold unit with extra large winder (Original standard winder will be suspended) |

| 5. | Both side heat slitting unit + additional winder |

FREE SPARE PARTS ONE LOT WITH MACHINE FOR

EIGHT SHUTTLES CIRCULAR LOOM (PER SET)

| No. | Item | Description and Quantity | Remark |

| 1. | Shuttle | 1 set | |

| 2. | HY-1014-1 vibrate rod long | 4 pcs | |

| 3. | HY-1014-2 vibrate rod short | 4 pcs | |

| 4. | HY-1017 cam skipper 26mm | 6 pcs | |

| 5. | HY-1018&19 connector 12mm | 4 sets | |

| 6. | HY-1020 movement rod | 4 pcs | |

| 7. | HY-1052 28T shuttle gear | 2 pcs | |

| 8. | HY-1056 wheel protector | 1 pc | |

| 9. | Oil dripping device | 2 pcs | |

| 10. | Tool box | 1 lot | |

| 11. | Blanket | 8 pcs | |

| 12 | Yarn scissor | 3 pcs | |

| 13 | Yarn hook | 4 pcs | |

| 14 | Solenoid valve | 1 pc | |

| 15 | Size weaving ring | 1 pc (Size as per customer request) |

MODÈLE STERIBER-C 150 MODÈLE STERIBER-C 150

MODÈLE STERIBER-C 150 MODÈLE STERIBER-C 150

COUPEUR TYPE UN ARBRE COUPEUR COUPE À UN ARBRE

SYSTÈME DE MACHINE COMPLÈTEMENT FERMÉ SYSTÈME COMPLÈTEMENT FERMÉ

INPUT FEED MANUEL MANUEL

CONTENANT D’ALIMENTATION DE SORTIE RÉCIPIENT

SYSTÈME D’ENTRAÎNEMEN T COUPLÉ DIRECTEMENT

COUTEAU DE COUPE MATÉRIAU ACIER ALLIÉ RÉSISTANT À L’ABRASION TRAITÉ À LA CHALEUR

STÉRILISATION STÉRILISATEUR LIQUIDE STÉRILISATION STÉRILISATEUR LIQUIDE 350 ML / PAR CYCLE

DE DECHARGE DE LIQUIDE PRESENCE

TEMPS DE TRAITEMENT 20 MIN – 3 CYCLES / HEURE

CAPACITÉ 50 LT / CYCLE – 150 LT / HEURE

PANNEAU ÉLECTRIQUE PANNEAU DE COMMANDE PLC OMRON

SYSTÈME DE RETOUR RETOUR AUTOMATIQUE DU BOURRAGE INSTANTANÉ

TRÉMIE D’ENTRÉE TAILLE 500 X 500 MM

HAUTEUR DE CHARGEMENT 1300 MM

PROCÉDÉ DE DÉCHARGEMENT CONVOYEUR D’HELEZONE

PUISSANCE MOTEUR 4 KW

DIMENSIONS 2300 X 760 X 1700 MM

POIDS 780 KG